Products Description:

1.1 SCOPE

This listed specification covers the design requirements and performance standard for the supply of optical fiber cable in the industry. It also includes HL premium designed cable with optical, mechanical and geometrical characteristics

Cable Type:Generally Anti-rodent ADSS

Application: Aerial Installation

1.2 Cable Description

cable possesses high tensile strength and flexibility in compact cable sizes. At the same

time, it provides excellent optical transmission and physical performance.

1.3 Quality

GL ensures a continuing level of quality in our cable products through several quality

control programs including ISO 9001.

1.4 Reliability

Both initial and periodic qualification testing are performed to assure the cable's

performance and durability in the field environments.

1.5 The cable are designed, manufactured and tested according tointernational

Standards As Follow:

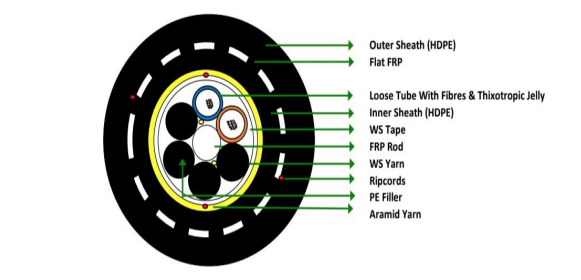

3.1 Cable Type: GL– Anti-rodent ADSS – Flat FRP

Characteristic:

1. ADSS Anti rodent with Double Jackets cable is designed for Aerial Installation with Stable performance and compatibility with all common fiber types

2. Aramid yarn as support messenger to assure the tensile and strain Performance, Glass yarn and FRP dielectric armor for anti-rodent protection with flat FRP armor as the strength member and also protect the cable from biting.

3. AT jacket mainly installed at existing 110kV or higher voltage power lines. PE jacket is adopted for below 110KV.

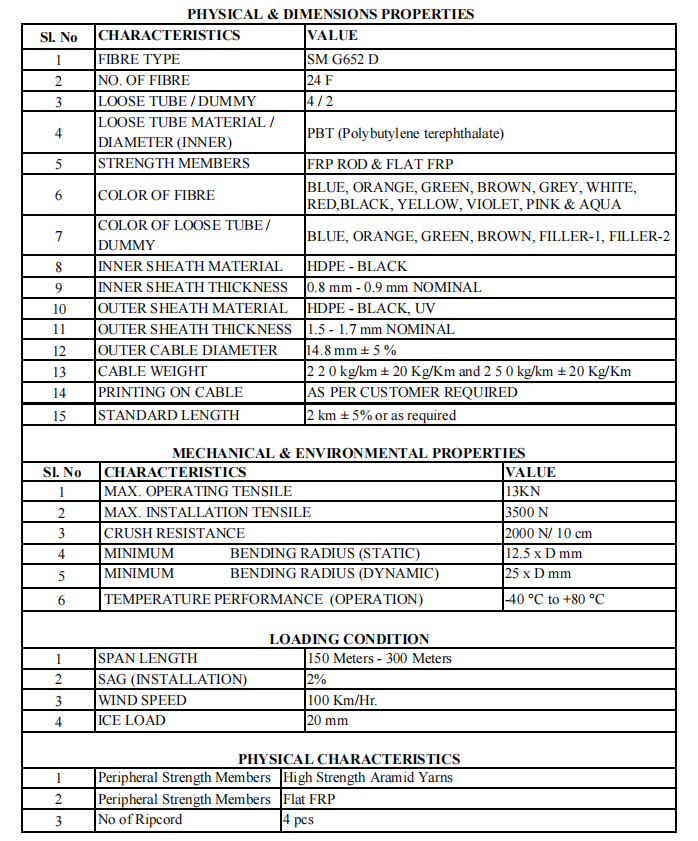

PHYSICAL & DIMENSIONS PROPERTIES

4. TEST REQUIREMENTS

Approved by various professional optical and communication product institution, GL also conduct various in-house testing in its own Laboratory and Test Center. She also conduct test

with special arrangement with the Chinese Government Ministry of Quality Supervision & Inspection Center of Optical Communication Products (QSICO). GL possess the technology to

keep its fiber attenuation loss within Industry Standards. The cable is in accordance with applicable standard of cable and requirement of customer. The following test items are carried out according to corresponding reference. Routine tests of optical fiber.

Mode field diameter | IEC 60793- 1-45 |

Mode field Core/clad concentricity | IEC 60793- 1-20 |

Cladding diameter | IEC 60793- 1-20 |

Cladding non-circularity | IEC 60793- 1-20 |

Attenuation coefficient | IEC 60793- 1-40 |

Chromatic dispersion | IEC 60793- 1-42 |

Cable cut-off wavelength | IEC 60793- 1-44 |

Tension Loading Test | |

Test Standard | IEC 60794- 1 |

Sample length | No less than 50 meters |

Load | Max. installation load |

Duration time | 1 hour |

Test results | Additional attenuation:≤0.05dB No damage to outer jacket and inner elements |

Crush/Compression Test | |

Test Standard | IEC 60794- 1 |

Load | Crush load |

Plate size | 100mm length |

Duration time | 1 minute |

Test number | 1 |

Test results | Additional attenuation:≤0.05dB No damage to outer jacket and inner elements |

Impact Resistance Test | |

Test Standard | IEC 60794- 1 |

Impact energy | 6.5J |

Radius | 12.5mm |

Impact points | 3 |

Impact number | 2 |

Test result | Additional attenuation:≤0.05dB |

Repeated Bending Test | |

Test Standard | IEC 60794- 1 |

Bending radius | 20 X diameter of cable |

Cycles | 25 cycles |

Test result | Additional attenuation: ≤ 0.05dB No damage to outer jacket and inner elements |

Torsion/Twist Test | |

Test Standard | IEC 60794- 1 |

Sample length | 2m |

Angles | ± 180 degree |

cycles | 10 |

Test result | Additional attenuation:≤0.05dB No damage to outer jacket and inner elements |

Temperature cycling Test | |

Test Standard | IIEC 60794- 1 |

Temperature step | +20℃ →-40℃ →+85℃→+20℃ |

Time per each step | Transition from 0℃ to -40℃:2hours; duration at -40 ℃:8 hours; Transition from -40℃ to +80 ℃:4hours; duration at +80℃:8 hours; Transition from +80℃ to 0℃:2hours |

Cycles | 5 |

Test result |

≤ 0.05 dB/km |

Water penetration Test | |

Test Standard | IEC 60794- 1 |

Height of water column | 1m |

Sample length | 1m |

Test time | 1 hour |

Test result | No water leakage from the opposite of the sample |

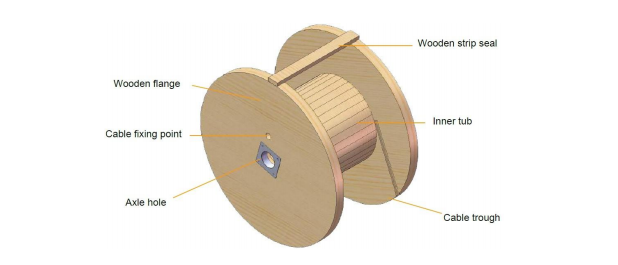

5. Packing and Marking

Each single length of cable shall be reeled on Fumigated Wooden Drum Covered by plastic buffer sheet

Sealed by strong wooden battens. At least 1 m of inside end of cable will be reserved for testing. Drum

length: Standard drum length is 3,000m±2% and 2000m or as required. Drum Marking (can according to

the requirement in the technical specification) Manufacturer name;

Manufacturing year and

month Roll---direction arrow;

Drum length;

Gross/net weight

Email:info@hanlan-tech.com

Email:info@hanlan-tech.com WhatsApp:0086 18073118925

WhatsApp:0086 18073118925